November 22, 2023

3d Printing Pointers + Less Complicated Cad

3d Printing Pointers + Easier Cad You can comply with the retraction calibration procedure I shared, to produce a calibration tower and locate the best value for your printer. But do it only after you discover the most effective temperature for your filament. Besides the belt tightening up problem, this kind of VFA result on the external walls can appear because of mini stepping issues and stepper electric motors which do not relocate uniformly. As a pointer, I recommend you do the Z balanced out calibration with your nozzle as well as bed heated to the very same temperature levels as when you leveled your bed. A bed probe can aid if you have an uneven print surface, as well as compensate for the tiny variations on your bed, but it can't amazingly fix your concerns.Exactly how do I get an excellent surface area finish in 3D printing?

Cura Setups Utmost Guide-- Settings Explained & Exactly How To Utilize

Every little thing, whatever listed below is either a level object or a lathe things. [newline] Every one of which was done in Illustrator, and imported as an EPS file into Infini-D 3D, textured then provided. Well the toolset in Illustrator is much better than any kind of 3D program I've experienced. So Illustrator is ALWAYS running in the background when I version. 2) As well as I put a layer of Scotch brand painter tape down on my glass bed, cleaned with alcohol. I can in fact manage all the elements of my maker ... even numerous I had no suggestion I can manage (and also still don't). Your personal data will be used to support your experience throughout this web site, to handle accessibility to your account, as well as for various other purposes explained in our personal privacy policy.3D Printing Jewelry – The Ultimate Guide - All3DP

3D Printing Jewelry – The Ultimate Guide.

Posted: Tue, 18 Oct 2022 07:00:00 GMT [source]

R & D Limelight: Issue Discovery In Steel 3d Printing, Multi-metal Design, Plus An Unique Design Technique

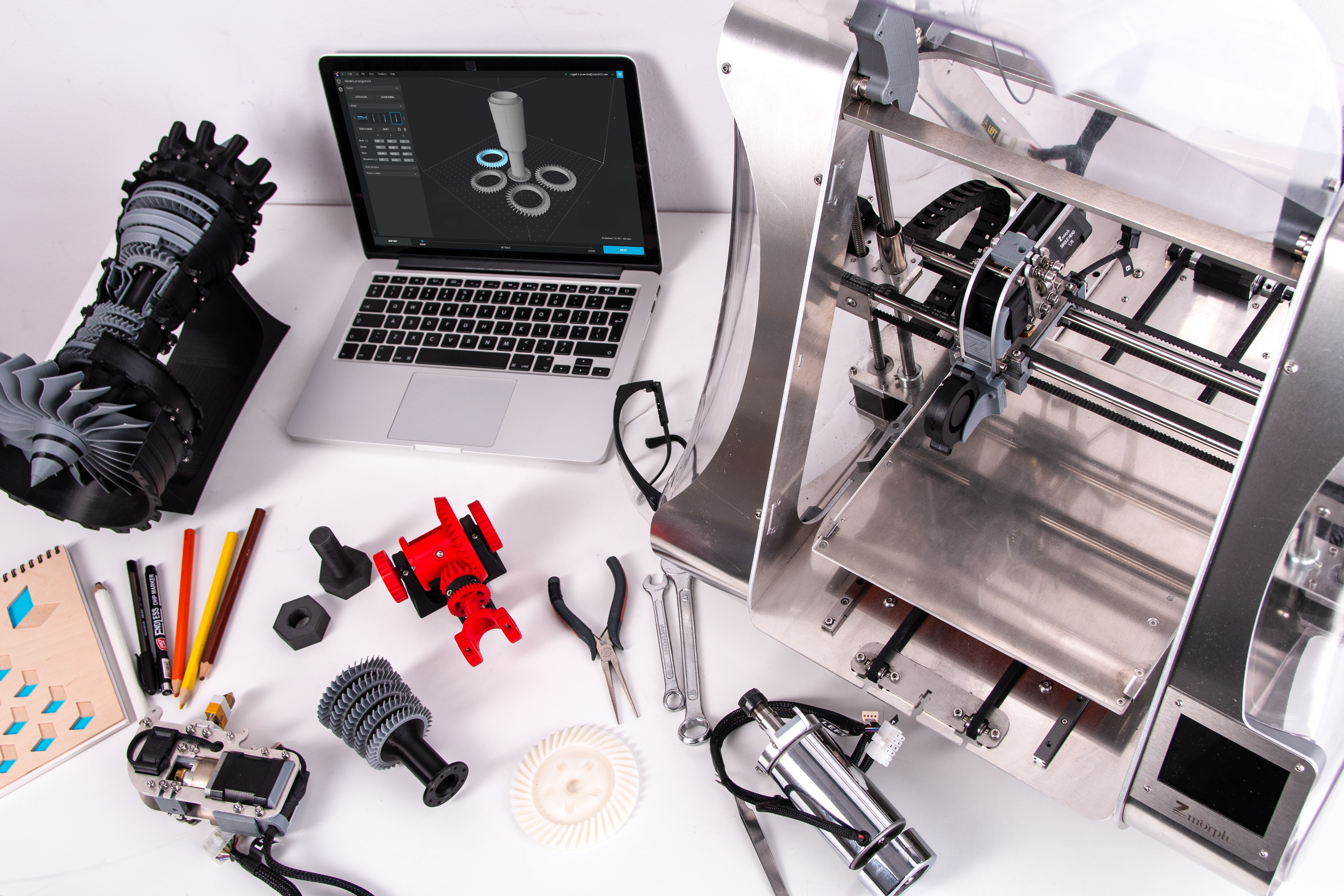

There are different Ways to Dry Your Filament so check out the write-up to figure out. To accelerate points, you have to select a basic pattern with couple of non-extrusion motions and minimal changes of direction. If you're not as well curious about appearances but intend to speed up the printing process, picking a lower resolution can assist you print faster. A slicer is a kind of software program designed to transform CAD documents right into a format that your printer can read and also comprehend. Three-dimensional printing can be laborious, specifically if you utilize an FDM printer. The melting, squeezing out, as well as air conditioning of filament takes time, and also you may question what are the enigmas of quick prototyping.Ready To Change Your Cad Documents Into A Personalized Component? Upload Your Designs For A Free, Instantaneous Quote

As we stated earlier, CAD is still a crucial component of the 3D printing process as well as, as a CAD customer, you might appreciate some software that can conserve you time in that sector as well. Assume critically regarding which facets of your design demand to be 3D published. Some functions could be implemented much more successfully with various other producing methods. When proper, integrate other parts right into your layout to save money on print time as well as cost or to enhance essential functions. Below are a couple of instances of where basic equipment assimilations or style adjustments can improve component success. PLA is just one of the most frequently utilized products in 3D printing.- When working with the decal sheets, remember that inks are water based.

- Prior to printing, add an additional resistance in between 0.5-1 mm to your model to offset any kind of warmth diminish or flaws.

- The reducing board lets me sand, hack as well as dig away at things without a reservation.

Social Links